IoT Solutions for the Manufacturing Industry

With mobile IoT connectivity, you can expand your value chain and create more value for your end consumers. Explore our IoT solutions for the manufacturing industry.

What We Offer for the Manufacturing Industry

From connected consumer products to industrial equipment, no matter what you manufacture, we can help you develop IoT solutions that work out of the box – anywhere your products go. We can help you roll out scalable, stable and secure IoT manufacturing solutions that meet your needs for coverage, quality and price.

Global IoT SIM Connectivity

with One Point of Contact

Industry-Leading

Security Measures

Top-Rated Service Team

on Call 24/7

Global Scale with One Solution

Wherever your products go, IoT Connect, our Managed Connectivity services provides you access to the best quality cellular connection, based on availability and the needs of your use case. Our Global IoT SIM cards can be pre-integrated to simplify your rollout, installation and lifecycle management.

We take care of all the agreements with local operators so you don’t have to. Using our extensive global roaming network, your products will connect to networks out of the box in nearly every market in the world. In countries where roaming is not available due to regulation, we can help you find viable solutions (including eUICC technology) together with our established local operator partners.

Get in Touch with Our People!

Let´s talk about the opportunities and challenges you are facing.

Connected Products Made Easy

We provide everything you need to successfully deploy and manage connected products around the world. Together with our partner network, we provide an end-to-end solution, from concept and design to monetization and operation over time. At the core of that end-to-end offering are IoT Connect, Telenor´s Managed Connectivity services and IoT Complete, Telenor´s end-to-end connectivity service.

Why Do Top Manufacturers Rely on Us?

- Faster time to market for connected offerings

- Reduced risk and cost with IoT connectivity as a service

- Future-proof solutions that last the entire product life cycle

- Peace of mind provided by guaranteed security and uptime

- Strategic insight and round the clock support

- Guaranteed service levels and data security

Trusted by the Best

For two decades, we have helped leading manufacturers succeed with pioneering IoT solutions. Learn more about their strategies, and how you can succeed with connected products.

Carpigiani: A Recipe for Gelato Success

How Husqvarna Is Reaching more Customers with IoT

IoT Enabled Refrigerators: A Case Study with ISA

Why Choose Mobile IoT Connectivity?

Mobile networks are well-tested and aren’t going away anytime soon. Our mobile IoT connectivity solution gives you access to well established global networks which use licensed radio spectrum, free of disturbances and congestion from competing networks.

Managed Connectivity allows you to conquer the complexity of IoT, we can help you simplify the production, rollout and management of your connected products. With our solution, your products use the best available mobile networks to securely connect to your network or the internet.

Why Mobile IoT?

- Established global networks and standards

- Easy to integrate connectivity

- High data rate

- Quality of service backed up by SLAs

- Future-proof for long term deployments

- Scalable and flexible

IoT Solutions in Manufacturing

Industries from manufacturing to mining rely on digital transformation to become more efficient and reduce human error. From real-time data analytics to supply-chain sensors, smart devices help prevent costly errors in industry. Embracing IoT in industrial manufacturing also makes fiscal sense: according to Gartner, 63% of enterprises expect they will achieve financial payback in 3 years for their IoT projects.

Beginning with optimization and continuing to responsive automation of production, IoT allows manufacturers to create smarter factories that operate more efficiently at a lower cost.

Connecting things also provides ways to better connect with people. With connected products, manufacturers can extend their customer relationships far beyond the assembly line.

What Does an IoT Solution for the Manufacturing Industry Look like?

An IoT solution can offer a wide range of possibilities for businesses, from a connected device that reports end-user behaviour to solutions that allow vehicles and machinery to operate autonomously.

IoT Use Cases in Manufacturing

Example of products we connect: Air handling units, air purifiers, water pumps, compressors, gensets, level monitors, construction equipment, elevators, garden equipment, industrial assembly tools, agriculture equipment, industrial filters, foodservice equipment, entrance solutions, heat exchanger.

Xylem: Making Every Drop Count with Connected Water Assets

IoT in Manufacturing - What can Manufacturers Achieve with Connected Products?

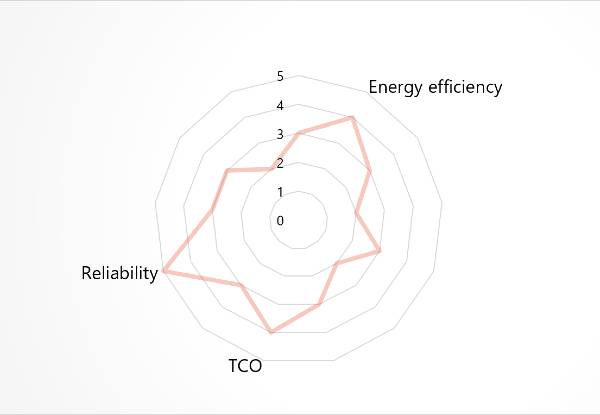

When product manufacturers set out to deliver customer services based on connected products it puts completely new requirements on connectivity. To be dependent on locally managed networks becomes a major limitation since access may be limited and reliability is not sufficient. Quality of service, uptime and global reach drives the use of mobile connectivity.

Telenor has more than 20 years of experience connecting industrial products at global scale. Based on these experiences we have built unique knowledge in how to connect large global fleets of products and we know how to support industrial equipment manufacturers who need to connect their products.

Telenor IoT has long experience in IoT for manufacturing and in guiding companies in the right connectivity technology selection, solution set-up, data optimization and how to operate and troubleshoot a connectivity solution at global scale.

We offer solution components that will be integrated in the customer solution, global SIM and connectivity management or a ready-to-use application enablement platform for connected products. Telenor also offers a complete service that integrates all components into a single service including everything from connectivity hardware to configurable IoT applications.

Our mission is to make IoT easy for industrial equipment manufacturers that want to focus on creating business, not troubleshooting mobile connectivity.

Connected assets can request service when they need it. This optimizes asset performance and frees up time for service personnel.

Connected assets allow for more precise inventory management, optimized logistics, quality control, and theft detection.

Optimizing parts purchasing, inventory and replacement is easier when connected products report what they need and when they need it.

To ensure performance and minimize downtime , all assets can be remotely monitored. If a problem occurs, an alarm is sent and product can adjust accordingly.

Augmented reality coupled with connected assets can be also used for training and remote operation.

Production becomes more flexible and responsive with unified systems of connected assets that collaborate in real-time, no matter where they are located.

Product development can now be based on real usage data, with offerings that adapt to end-user needs.

Connected products allow manufacturers to create new business models and streams of revenue with aftermarket services and digital add-ons.

Connected products create an easier path to consumer adoption and interaction when customers can skip up-front investment and pay for services on a per-usage basis.

Remote configuration and upgrading enables faster release of software improvements, and allows a connected product to evolve and adapt over time.

Addressing the needs of customers and partners becomes easier with increased data from products and assets.

Connectivity Technology Requirements in IoT for Manufacturing

Manufacturing use cases are still dominated by wired connections. However, modern IoT technology allows for broader functionality and are better applied in hazardous conditions where wires may increase the risk of equipment failure. Hence, wireless technology will gradually replace wired technology, not only in green- but also brownfield settings. Industrial manufacturing use cases require connectivity with good indoor coverage, often in industrial regions, high device density and low cost. Machines are often in close proximity to each other with a high number of sensors and frequent data submission. Decade-old factory equipment was not designed to be connected and thus needs to be retrofitted with sensors and connectivity. The fabric network therefore needs to be adaptable to a mix of both legacy and new machines and be able to scale up easily as new machines are being connected.

LoRa, Sigfox and Wi-SUN are common technologies offering good indoor coverage, reliability and low cost (after the initial investment in setting up the network). Cellular technologies such as 3G, 4G and 5G can also be a suitable alternative for companies within industrial manufacturing, eliminating the need to set up and maintain private WiFi and providing high quality of service through SLAs.

Related Content on IoT for Manufacturing

Please feel free to download these white papers with insights on IoT for manufacturing and

industrial IoT solutions.